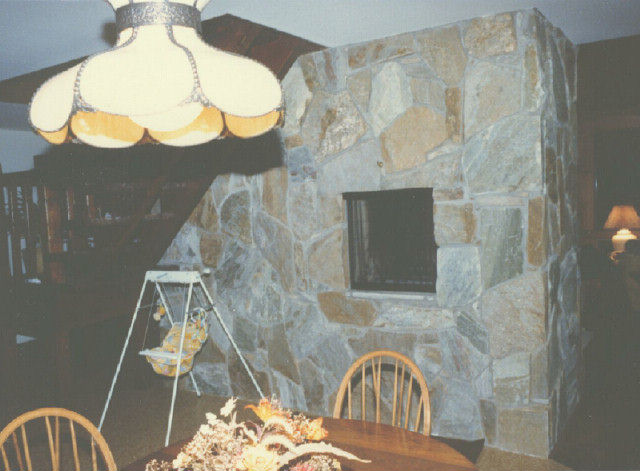

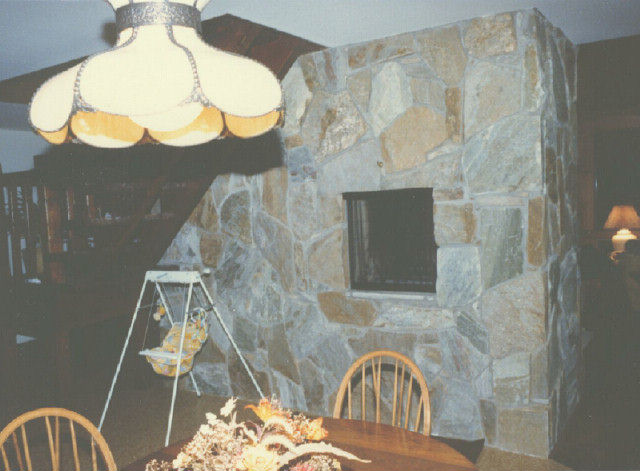

This is one of the finest pieces of stonework I ever built. It was for a painter named Jim Menone, on Panther Road in Vld. It took more than ten tons of stone, and measures ten feet wide on the face and five feet wide at the sides, rising up to the cathedral ceiling. It is open all around, one can pass through to the kitchen on either side. There is a wrap-around stairway going up the right side that leads to a loft overlooking the living room, so the fireplace construction also supported a portion of the loft. The building inspector gave us a hard time at first, until I showed him that there was more than three feet of solid masonry between any part of the firebox and the wood framing. Those building inspectors can be scary when they have no idea what they are talking about. This fireplace also has a smaller, two feet wide, full masonry fireplace in the back (kitchen) side primarily for cooking. Look at the corners; the stones are nicely lapped each way. Many of the stones weigh over a hundred pounds, and it was a daunting challenge. Almost all of our construction crowd got their hands in this one. Uncle Clyde laid a few of the stones, and Ed of course, and Bob and Roy helped too. The only person that didn't help at all was the missus of the house. If that man is still married to that woman he is guaranteed sainthood. I'll leave it at that.

This fellow was a friend of one of my fellow bricklayers, and he wanted a fireplace in his house, so it began. He bought some beautiful marble with many colors running through it. One day the dump truck came and dumped it into a pile in his yard, and we were on our way. I have to give Tom and Jerry some credit, because part of their deal was also to provide labor, so they mixed the cement and carried some of the materials inside for me. The marble in this one is some of the finest I ever worked with, but it was also some of the hardest. It is mixed with quartz and flint (extremely hard), and the cutting and fitting was cumbersome. A good eye saves a lot of hacking, and I would go out and stare at the pile of stones on the ground looking for one to fit the shape I needed inside. Jerry realized what I was doing, and he started to spread the pile out so that I could get a good look at virtually every stone. Even then I needed to search and often had to turn the stones looking for just the right angle or shape to fit with those alread laid.

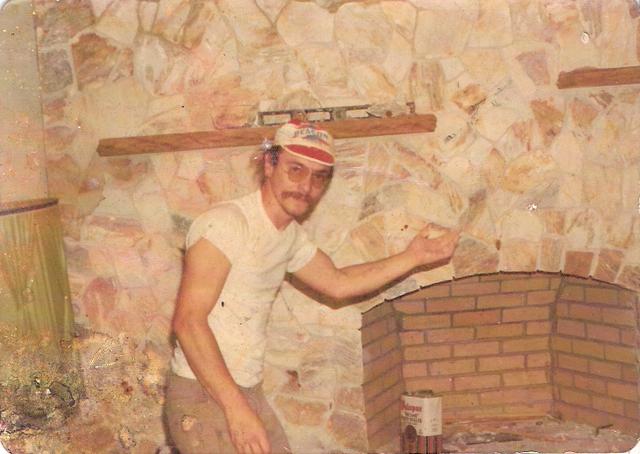

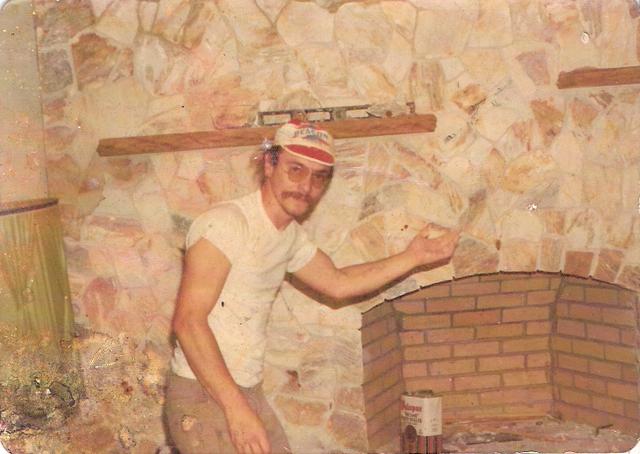

Uncle Clyde had spoken of his desire to have a fireplace in his house for several years, and even though he was a bricklayer, he had never built a fireplace. He spent most of his bricklaying career building the furnaces in the glass factories in the region; primarily Owens-Ilinois.

At last the time was right. I was available, we had help, and he was ready to alter his house. The brick ones are actually relatively easy compared to the stone jobs, so we knocked his out pretty handily. It, too was a family affair, and while I think more of the cousins got there hands in the construction cousin Roy made it into this picture.

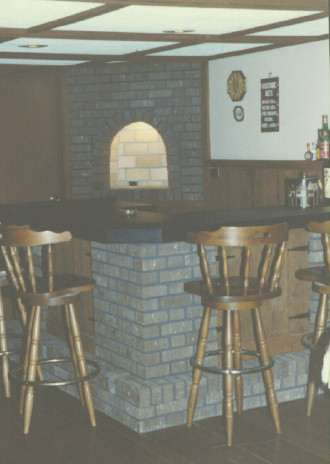

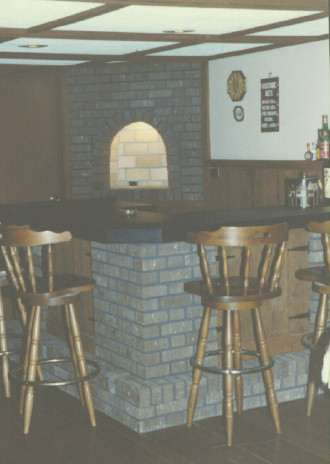

Tommy's fireplace actually preceded Jerry Costas above. Tommy wanted a fine fireplace in the basement he was finishing into a nice hangout. He picked up these beautiful bricks that were brown with cream colored streaks running through them. I asked Tom and His wife what they had in mind, and his wife said that she had seen a wall someplace where the bricks had been laid with the mortar left hanging out without being cut off or struck; what you would normally see on the back side of a brick wall that could not be reached for proper finishing. Some people like that look, and maybe it has it's place, but not in one of my creations!

I told her that I would not do such work, and that if she wanted that effect they would have to get someone else to do it. They wanted me to do the job, so I dry stacked a couple samples including the Flemish bond shown in the final product. There are several variations of Flemish bond but full Flemish bond uses a half brick and a whole brick in every course of bricks with the half brick falling over the whole in the course below. That takes a little longer, more attention, and can't be sloppy. I made my standard proposal that used to be safe to agree to on a handshake. I told them, as I did with most of these fireplaces, that if they did not like it when it was done, that they would not have to pay me. Try that today!

In addition to the full Flemish bond, it also has a stepped hearth and a full sprung arch. Just building the form for that is almost a dying art. I did these works on weekends, and charged Tommy and Jerry about three hundred dollars for each of these jobs (in the 70's). One Sunday, working in Tommy's basement, he had a couple visitors after church let out. His aunt and uncle came, and got folding chairs and set them up to watch me work on the fireplace. A few minutes later another couple came, brought out more folding chairs, and sat to watch me work. It became a small affair with a group of his relatives and friends there to watch a fireplace get built. The progress was halfway done or more, and the wooden form was in place as I built the arch up more and more. The form cannot be safely removed until the arch is complete and there is considerable weight bearing on it; more weight gives it greater strength. The icing on the cake with this gathering came when one of the aunts asked me how they would be able to build the fire with that wood in the way. Oy! I told Tommy I had to take a break, and I went to get some beer and didn't return until most of the cars were gone.

Esteban built many fireplaces.

Folks enjoy the stonework & firelight for decades & generations.

Folks enjoy the stonework & firelight for decades & generations.

I built this one on Vine Road for Jerry Costa who lived a couple houses over from Tommy Galbiati and across the street from Butch Marolda. Jerry wanted the stone mantle pieces to be strong enough to hold his bowling trophies. I climbed up and laid on each one of them to demonstrate their strength.

Unc wanted this fireplace for years, and we finally did it. He worked on the giant furnaces in the glasshouses, but never built a fireplace before. He and I did it together with help again from Ed, Bob and Roy and others.

Tommy's fireplace actually preceded Jerry Costas above.

Tommy wanted a BBQ thingy in his basement too, but this one is not a complete firebox type. I built the face to match the big fireplace, and put the firebricks inside for effect, but the rest is just a metal flue to the outside.

Tommy also had to have a matching bar, of course.

Tommy also had to have a matching bar, of course.

I remember when Clip took me with him to build a fireplace when I was about four or five years old. He had the stacks of bricks close to where he was working, and that is important for such work, but my job was to turn them to all face the same way so that he could just pick them up and lay them faster without flipping them around to get the face right. I remember when he took us on the job while building the addition to the school in Quinton. Eduardo and I fooled around some, but at the end of the day I had to roll up the water hoses. I think I was about five years old then. The first time I felt daring enough to climb up on some scaffolding was the first time that I learned that it looks much higher from up there, and it is much easier climbing up over the edge of the planks than it is climbing down. Over the years Eduardo and I cleaned equipment, painted scaffolding, wheelbarrows, stacked pallets so they could be returned for the deposit, and much more. Once we were near the end of, or out of school, the real work came. We labored first, then clamored to become bricklayers. We built that HoJo on Route 3 in Plattsburg. I became the dedicated mixer man for the stonemasons we'd subcontracted with to do the front of the restaurant. Clip never got too deep into stonework. Those masons taught me some about the stone craft, including the 'drypack' method, which I later applied in my own stone jobs. I also got to work with 'Frenchie' ( Maurice Roquefort - the Canadian stonemason ) when Clip used him to complete stonework for special clients. His other nickname was Budweiser, and he easily drank a case a day, but as his tender I learned more about the stone craft, and the art of fireplace building.

An Enigma Within a Conundrum